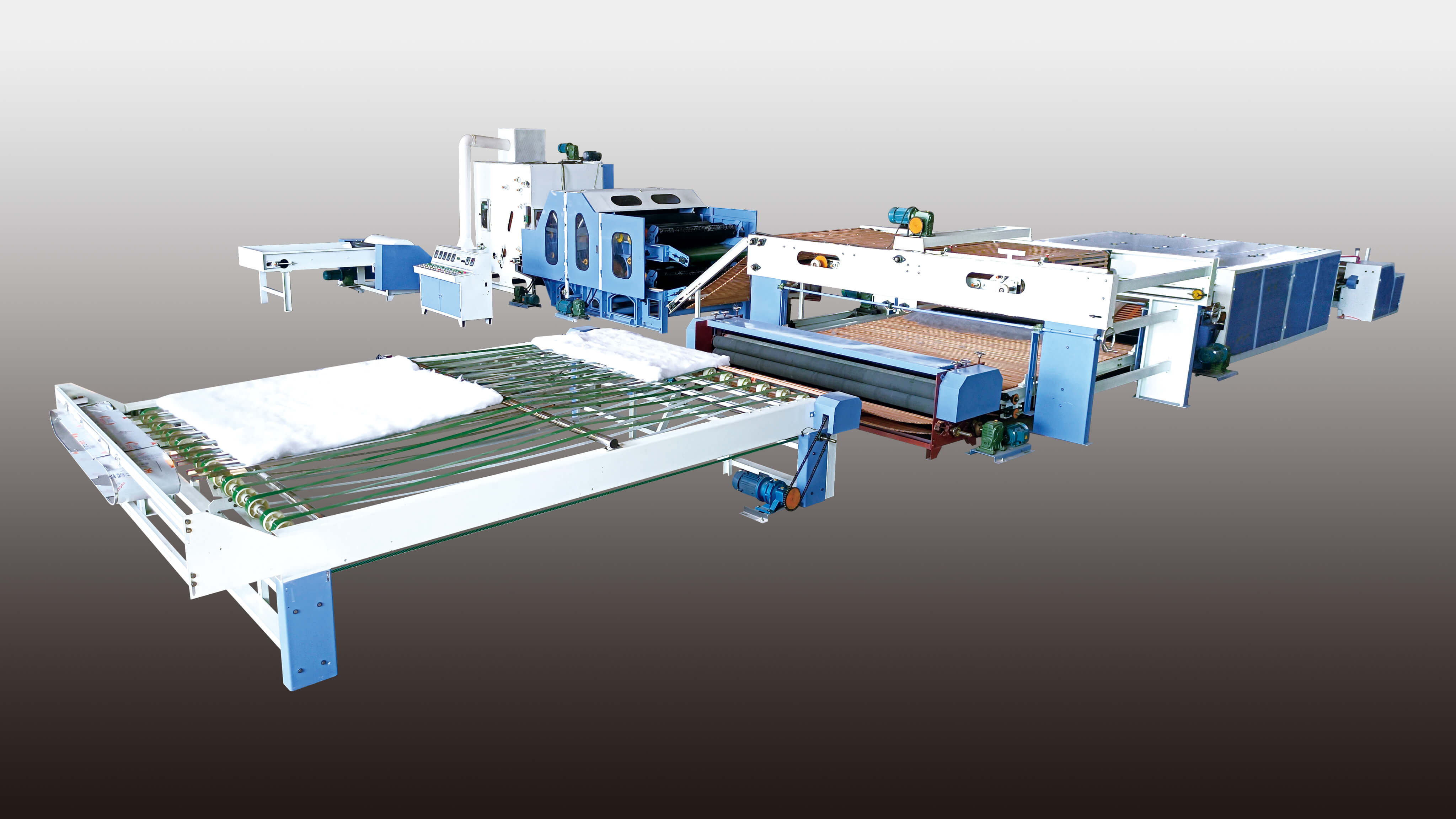

Polyester Wadding Roll Making Machine

product presentation

1.Electric Weighing Bale Opener : Electronic weighing raw material ,Mix different specifications of raw materials in proportion

2.Opening Machine : Opening tight ordinary fiber and low melt fiber into loose state

3.Feeding Box : To mix the opened fiber and low melt point fiber and transfer them to carding machine

4.Carding Machine : Opening and cleaning the fiber, carding into mesh layer

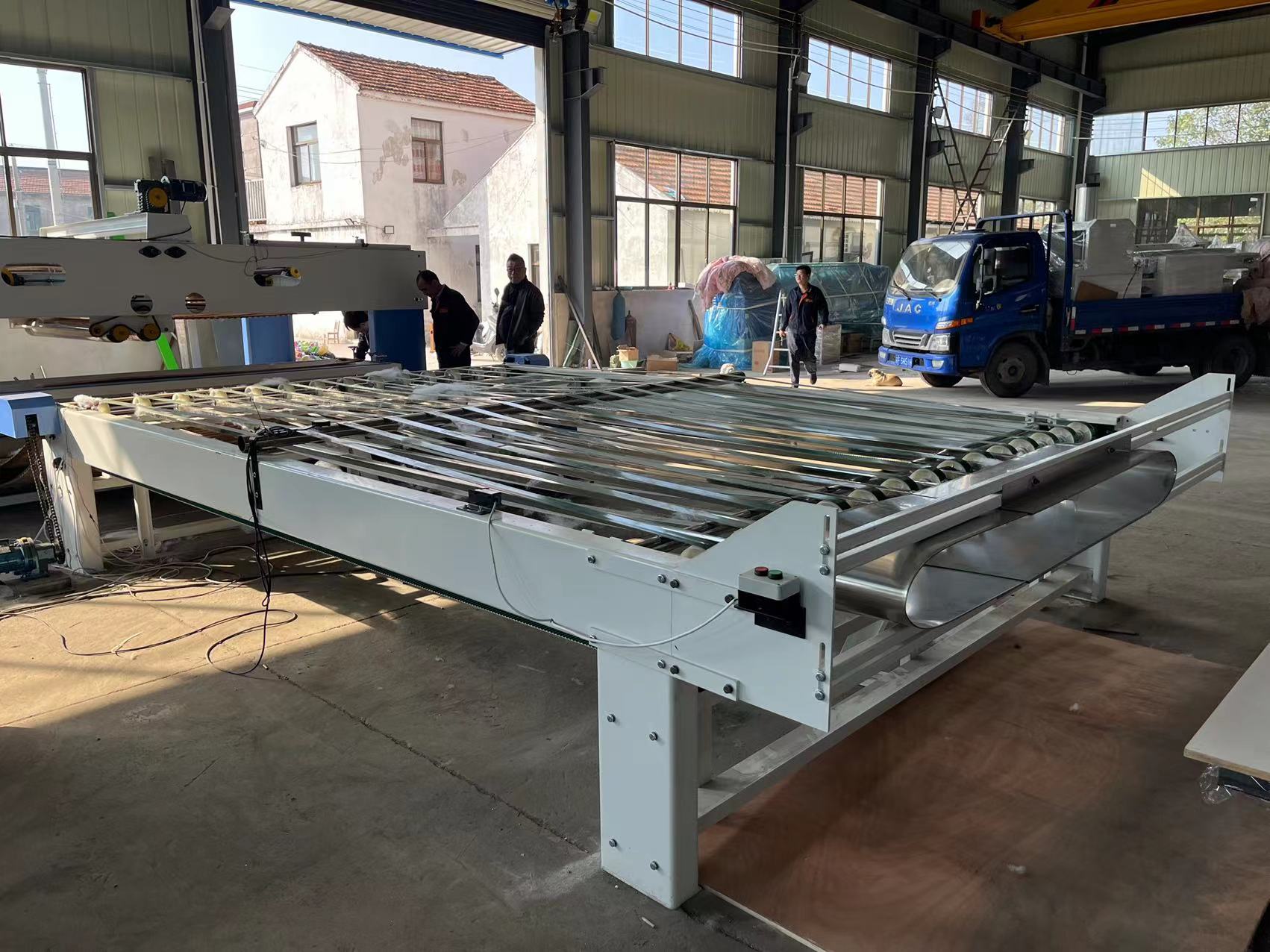

5.Cross Lapper : To fold and pave the fiber mesh into certain width and thickness evenly after carding

6.Oven : After high temperature ,the low melt point fiber melting,evenly distributed in ordinary fiber,when the fiber layer out of oven,the melting low point fiber will be cold,then combine the ordinary fiber together like glue

7.Ironing Machine : To make the finished product surface more smoothly

8.Cutting & Rolling Machine : Edge cutting,Cross cutting to get a certain width wadding ,then rolling to certain length roll.

Parameter

| Item | Size | Weight | Power | Remark |

| Opening Machine | 3100*1060*1040MM | 950KG | 7KW | - |

| Feeding Box | 2015*1515*2320MM | 1700KG | 3KW | - |

| 1230 Carding Machine | 3200*2300*2300MM | 6600KG | 18KW | Optional 850,1850 Carding |

| Cross Lapper | 4600*2300*1760MM | 1200KG | 6KW | - |

| Electric Oven | 2500*3400*1230MM | 2000KG | 60KW | Optional,Gas oven |

| Cutting & Rolling Machine | 4160*1500*1260MM | 1600KG | 3KW | Optional |

| Electric Ironing Machine | 3300*900*2200 MM | 1200KG | 15KW | Optional , Oil Ironing Machine |

| Electric Weighing Bale Opener | 3700*1700*2100MM | 1200KG | 7KW | Optional |

| Needle Punch Machine | 3400*1200*2100 MM | 5000KG | 11KW | Optional |

Raw materials and finished products

packing