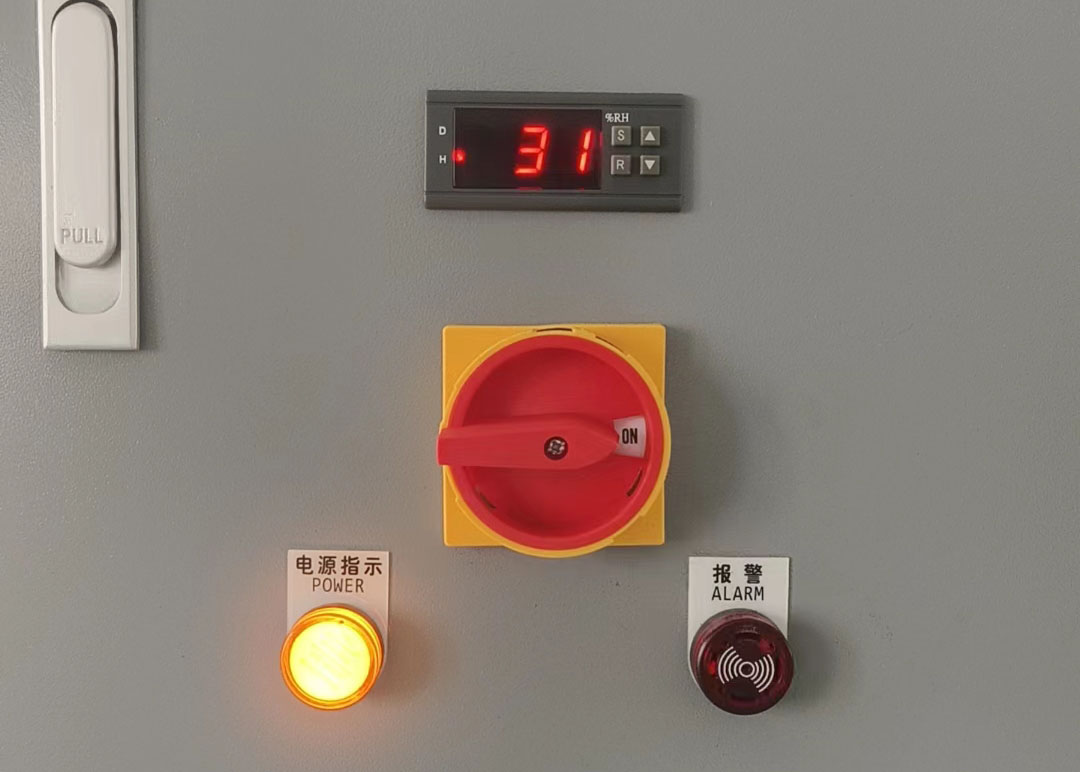

Cambodian down jacket manufacturer has received a repeat order from an old customer for 10 down jacket filling machines KWS690-4. The down jacket filling machine is known for its speed, precision, and innovative features such as static elimination and humidification functions. These functions not only ensure efficient filling but also effectively reduce the trouble caused by static electricity to workers during the production process.

The KWS690-4 is the most advanced flow-type, direct-filling down jacket filling machine available in the market. Its filling speed is exceptionally fast, making it a popular choice among manufacturers. The company also produces fully automatic weighing and filling machines, quantitative pillow filling machines, goose down quilt filling machines, and fully automatic down fiber pillow filling machines, all of which have passed ISO and CE certification, ensuring stable performance, quality, and safety.

The down jacket filling machine’s static elimination and humidification functions are particularly beneficial for workers, as they help in reducing the inconvenience caused by static electricity during the production process. This not only enhances the efficiency of the filling process but also ensures a safer and more comfortable working environment for the employees.

The company’s commitment to producing high-quality and innovative filling machines has earned them the trust and loyalty of their customers, as evidenced by the repeat order for the KWS690-4 machines. With a focus on efficiency, precision, and worker safety, the Cambodian down jacket manufacturer continues to lead the market with its advanced and reliable filling machines.

Post time: May-28-2024